About Us

Dongguan Meidelin Machinery Technology Co.,Ltd

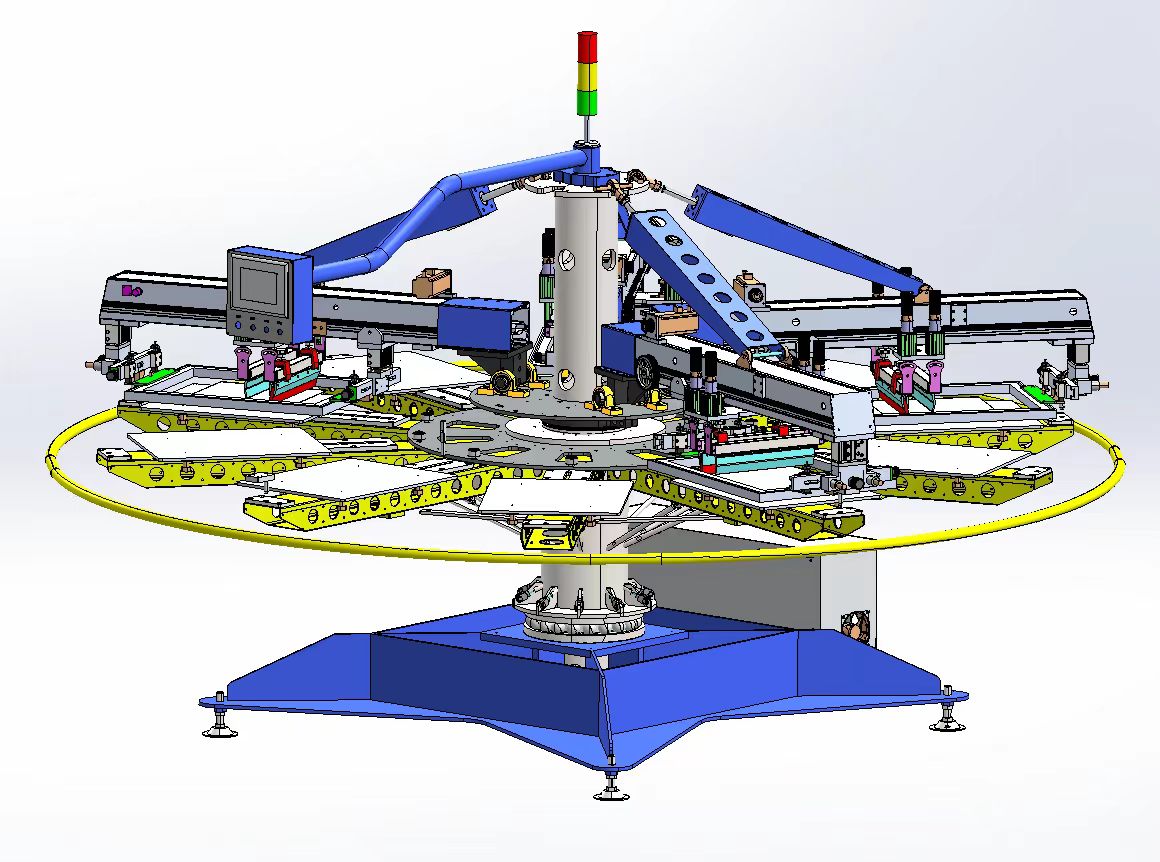

Dongguan Meidelin machinery technology co. Itd is a professional manufacturer and service provider of intelligent machine. The automatic screen printing machine and digital printing machine is our major product,we are also proud of them.

Our company was founded in 2014,and based on Kinwah &Dopsing which is the best and largest manufacturer of the narrow fabric printing and drying equipment,and thanks to that we really focus on the market. Due to relying on our own strong R&D and manufacturing strength,we created a very high reputation in the industry. Now,our product as far afield as India,Argentina,

Vietnam,Combodia,Burma,Bandladesh,Canada,Turkey and soon.

The advantage of our products:Separate production,timely delivery,quality assurance,product diversification,be widely popular,unique and practical.

Why choose us?

Stable quality and precise positioning enable multiple repeated color registrations without misalignment, thus meeting the requirements for fine dot printing.

Stable quality and precise positioning enable multiple repeated color registrations without misalignment, thus meeting the requirements for fine dot printing.

The all-electric printing machine integrates perfectly with common tables available on the market and can operate automatically without table replacement.

The all-electric printing machine integrates perfectly with common tables available on the market and can operate automatically without table replacement.

The all-electric printing machine is equipped with a simple and fast plate-matching device, and no plate re-replacement is required after the initial plate matching.

The all-electric printing machine is equipped with a simple and fast plate-matching device, and no plate re-replacement is required after the initial plate matching.

Fully electric step-by-step control enables arbitrary adjustments of screen height, squeegee pressure, and printing speed.

Fully electric step-by-step control enables arbitrary adjustments of screen height, squeegee pressure, and printing speed.

Automatic functions including forward movement, backward movement, turning, continuous printing, and skip-printing reduce labor requirements by over 60%.

Automatic functions including forward movement, backward movement, turning, continuous printing, and skip-printing reduce labor requirements by over 60%.

It features straightforward operation with a one-button start function and convenient maintenance with internet-based remote maintenance capabilities.

It features straightforward operation with a one-button start function and convenient maintenance with internet-based remote maintenance capabilities.

Fully digital control with process completion signal indication, ensuring high accuracy.

Fully digital control with process completion signal indication, ensuring high accuracy.

The heating tube and heating plate are integrated into one unit, featuring safety, durability, and uniform heat distribution.

The heating tube and heating plate are integrated into one unit, featuring safety, durability, and uniform heat distribution.

Pressure can be adjusted arbitrarily; it adopts an integrated track, and the sliding base plate is lightweight and stable, making it widely applicable to factory assembly line operations.

Pressure can be adjusted arbitrarily; it adopts an integrated track, and the sliding base plate is lightweight and stable, making it widely applicable to factory assembly line operations.

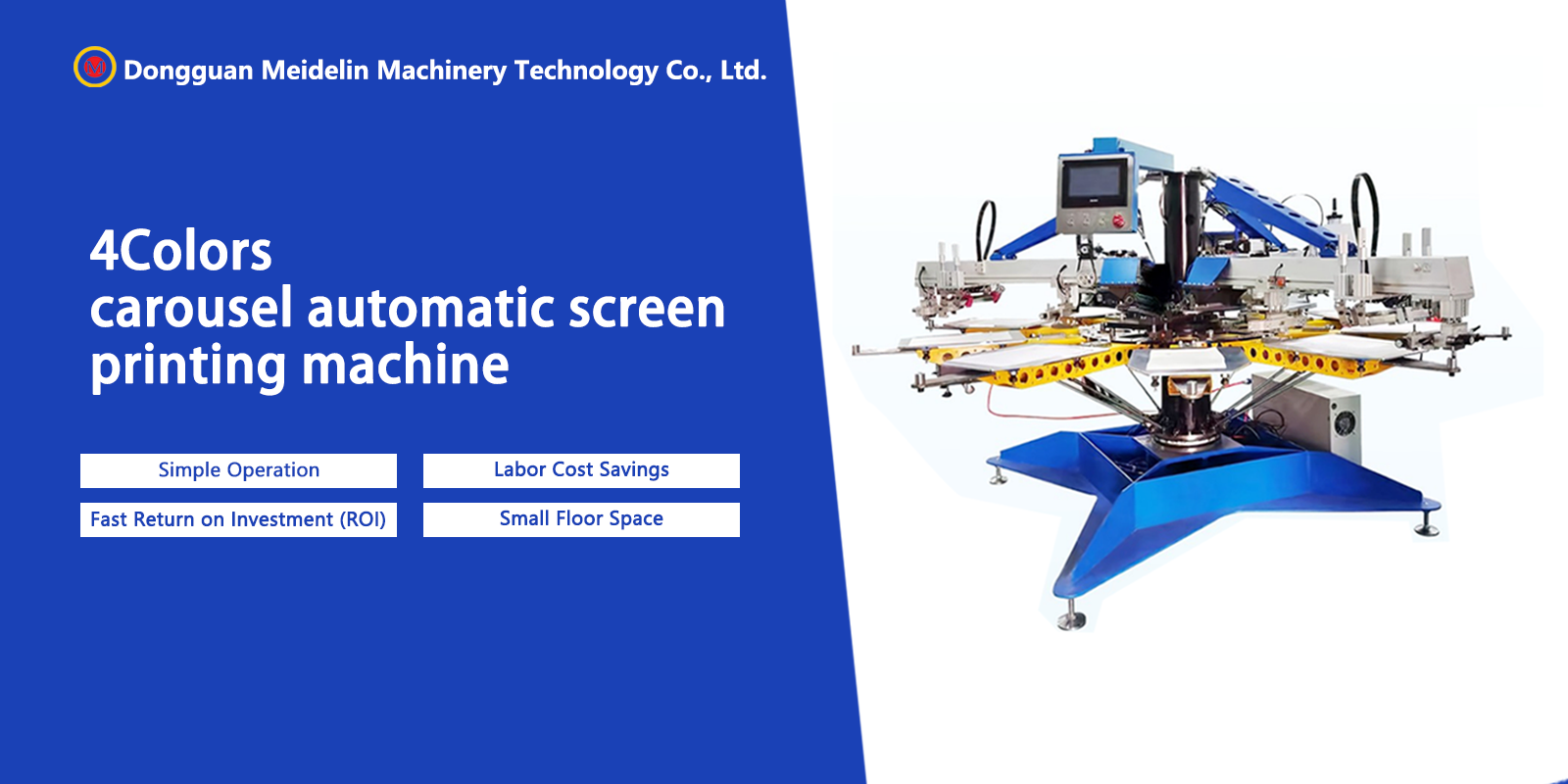

Fast return on investment: You can recover your investment within 1 to 2 months.

Fast return on investment: You can recover your investment within 1 to 2 months.

Simple operation: Unlike the elliptical printing machine which requires four operators to start up, only one operator is needed for this one.

Simple operation: Unlike the elliptical printing machine which requires four operators to start up, only one operator is needed for this one.

Save labor: One person can operate one machine. Reduce labor costs.

Save labor: One person can operate one machine. Reduce labor costs.

Meet the needs of small-order production: Suitable for the current market and Taobao's small-batch order requirements of approximately 50 to 3,000 pieces.

Meet the needs of small-order production: Suitable for the current market and Taobao's small-batch order requirements of approximately 50 to 3,000 pieces.

Small floor space requirement: The machine has a diameter of 3 meters, no additional manual printing table is needed, and the automated equipment can pass the environmental protection assessment.

Small floor space requirement: The machine has a diameter of 3 meters, no additional manual printing table is needed, and the automated equipment can pass the environmental protection assessment.

Digital printing can be flexibly added as an optional configuration, featuring low investment, high returns and minimal labor requirements.

Digital printing can be flexibly added as an optional configuration, featuring low investment, high returns and minimal labor requirements.

The overall structure of the equipment is stable, not easily deformed, operates smoothly with low noise, and the workbench can switch between manual and automatic operation modes.

The overall structure of the equipment is stable, not easily deformed, operates smoothly with low noise, and the workbench can switch between manual and automatic operation modes.

This machine applies pressure in a gentle manner, with fully automatic control; the pressure is stable and uniform, reaching up to 500kg/cm.

This machine applies pressure in a gentle manner, with fully automatic control; the pressure is stable and uniform, reaching up to 500kg/cm.

It adopts electronic digital constant temperature control with high accuracy (±1-2℃), and electronic time control, also with high accuracy.

It adopts electronic digital constant temperature control with high accuracy (±1-2℃), and electronic time control, also with high accuracy.

The pressure can be adjusted, it is easy to operate, and is widely used in factory assembly line operations; it also has an elegant appearance.

The pressure can be adjusted, it is easy to operate, and is widely used in factory assembly line operations; it also has an elegant appearance.

The workbench surface has undergone special treatment and can be used for printing sublimation, heat transfer, heat stamping, gold stamping and other products.

The workbench surface has undergone special treatment and can be used for printing sublimation, heat transfer, heat stamping, gold stamping and other products.

.jpg)